Nova Power Grip 409 2-K

2K PU FOR REPAIR AND BONDING

High filling capacity and unique adhesion.

Can be sanded, tapped or drilled very quickly.

For shorter working time please have a look at Nova Power Grip 401 2-K and 403 2-K.

Packaging

| SKU | EAN | Description | ||

|---|---|---|---|---|

|

590419000 - 5415207000619 - Nova Power Grip 409 2-K - cartridge 250ml | 590419000 | 5415207000619 | Nova Power Grip 409 2-K - cartridge 250ml |

Description

Is a superstrong 2-component adhesive with long open working time to bond spoilers, panels, bumpers,... Nova Power Grip 409 2-K is the ideal adhesive for universal repairs and bondings with a long working time. Nova Power Grip 409 2-K approaches the strength and flexibility of synthetic materials. Nova Power Grip 409 2-K can be sanded quickly, both on thin and thick layers. Nova Power Grip 409 2-K is suitable as both an adhesive and repair system.

Application

Automotive:

- gluing ferrous and non-ferrous metals, repairing damaged screw thread, nonweldable engine components such as ALU, zamac, ... .

Industry:

- repairing non-weldable machine and engine components.

- repairs of sliding and pin tracks.

- repairs of split rotors or blades of ventilators and pumps.

- repairing pump houses and butterfly valves.

- gluing ferrous and non-ferrous metals.

Technical information

Nova Power Grip 409 2-K

2K PU FOR REPAIR AND BONDING

- Basis: polyurethane.

- Smell: typical.

- Color after mixing: black.

- Mixing time (23°C): 5 minutes.

- Acting time (23°C): 8 to 10 minutes.

- Can be sanded/manipulated: after 60 minutes.

- Can be painted on: after 2 hours.

- Elastic strength (%): 80%.

- Tensile strength: 2620 N/cm².

- Shear strength: 1378 N/cm².

- Temperature resistance: 90°C continuous.

- Adherence: very good adherence to most plastics, polyesters, ferrous and non-ferrous metals, enamels and varnishes surpasses the cohesion of surfaces such as concrete, stone, wood,...; more than 2N/mm² on metals (practical calculated value).

- Chemical resistance: resistant to many acids, alkalis, oils, greases, petrol, heating oil, many solvents, salt solutions, aggressive vapours and sea air,...; not resistant to strong solvents.

- Hardening: no shrinkage.

- Min. processing temperature: 8°C.

- Electrical resistance > 109Ohm.

- Solids content: 100%.

- Shelf life: 24 months, keep dry, cool and frost-free.

- Safety measures: consult the Safety Data Sheet.

Instructions

As from 24 August 2023 adequate training is required before industrial or professional use.

Substrate preparation

- Clean with Safety Clean and/or Multifoam.

- Sand the material.

- Remove all dust.

- Degrease with Safety Clean and Multifoam.

- Blow dry.

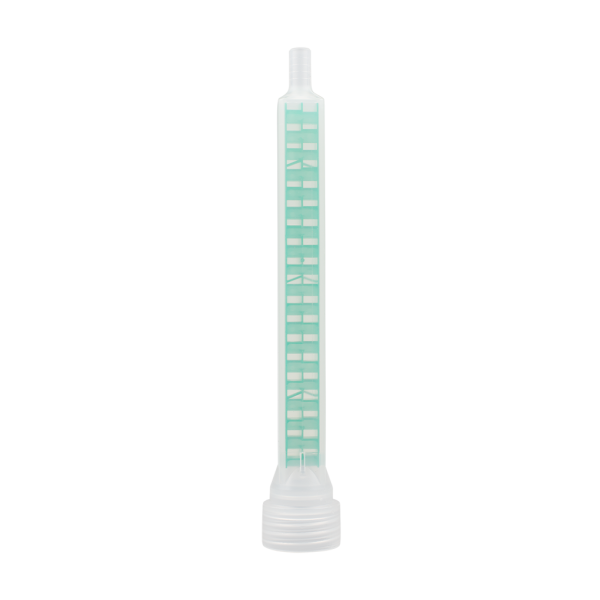

Cartridge preparation

- Remove the cap from the cartridge.

- Place the cartridge in the gun.

- Pump until both components flow out of the cartridge.

- Place the mixer tip on the cartridge and, if necessary, cut off the nozzle to enlarge the opening.

- First spout out 2 cm of product.

- Apply on a clean and dry substrate.

- Place a new mixer tip after a 5-minute break.

Storage

- Remove mixer tip.

- Clean cartridge.

- Put cap back in place.

For a perfect finish (such as lacquering) we recommend applying a flexible plastic putty.