Nova Power Grip 401 2-K

2K PU FOR SUPER FAST REPAIR AND BONDING

High filling capacity and unique adhesion.

Can be sanded, tapped or drilled very quickly.

If more working time is required, please see Nova Power Grip 403 and 409.

Packaging

| SKU | EAN | Description | ||

|---|---|---|---|---|

|

590411000 - 5415207000633 - Nova Power Grip 401 2-K - cartridge 250ml | 590411000 | 5415207000633 | Nova Power Grip 401 2-K - cartridge 250ml |

Description

Nova Power Grip 401 2-K is a superfast assembly and repair adhesive to glue or repair headlight supports, bumpers, decorative strips, clips for door cladding,... Repairs and gluing of hard, flexible, semiflexible and fibre-filled plastics, plastics, painted steel, stone, concrete, melamine, wood,... Nova Power Grip 401 2-K approaches the strength and flexibility of synthetic materials.

Application

Automotive:

- repairs hard and flexible plastics with a very fast drying time.

- repairs headlights, bumpers, decorative strips,... where fast drying time is required.

Industry:

- repair of hard and flexible plastics with very fast hardening.

- quickly glues ABS, SMC, PC, HPL, Melamine, whole rattan, wood, stone, ... .

- quickly glues insulating materials like Styrodur, Rock wool, Rock pannel.

Technical information

Nova Power Grip 401 2-K

2K PU FOR SUPER FAST REPAIR AND BONDING

- Basis: polyurethane.

- Smell: typical.

- Color: black.

- Mixing time (23°C): 50 seconds.

- Acting time (23°C): 1 to 2 minutes.

- Can be sanded/manipulated: after 10 minutes.

- Can be painted on: after 60 minutes.

- Elastic strength (%): 70%.

- Tensile strength: 2620 N/cm².

- Shear strength: 1378 N/cm².

- Temperature resistance: 90°C.

- Adherence: very good attachment to most plastics, polyesters, ferrous and non-ferrous metals, enamels and varnishes surpasses the cohesion of surfaces such as concrete, stone, wood,... more than 2N/mm² on metals (practical calculated value).

- Chemical resistance: resistant to many acids, alkalis, oils, fats, petrol, heating oil, many solvents, salt solutions, aggressive vapours and sea air, not resistant to strong solvents.

- Hardening: no shrinkage.

- Min. processing temperature: 8°C.

- Electrical resistance: > 109 Ohm.

- Solids content: 100%.

- Important: less good to poor adhesion can occur on plastics such as PE, PPU and silicones. Test first.

- Shelf life: 24 months, keep dry, cool and frost proof.

- Safety measures: consult the Safety Data Sheet.

Instructions

As from 24 August 2023 adequate training is required before industrial or professional use.

Substrate preparation

- Clean with Safety Clean and/or Multifoam.

- Sand the material.

- Remove all dust.

- Degrease with Safety Clean and Multifoam.

- Blow dry.

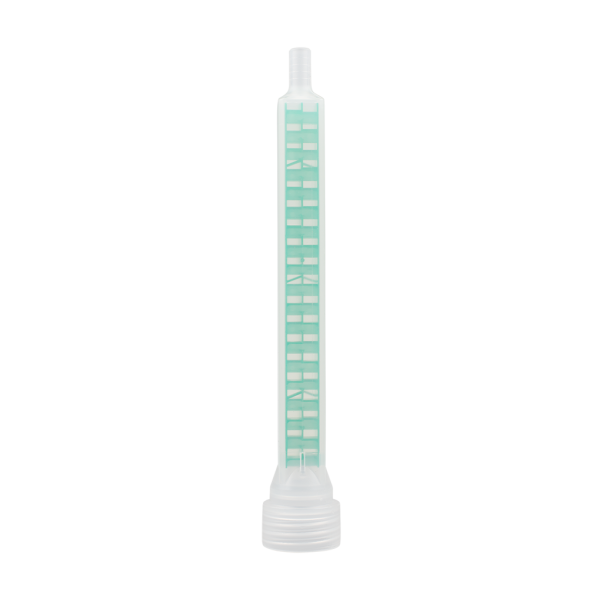

Cartridge preparation

- Remove the cap from the cartridge.

- Place the cartridge in the gun.

- Pump until both components flow out of the cartridge.

- Place the mixer tip on the cartridge and, if necessary, cut off the nozzle to enlarge the opening.

- First spout out 2 cm of product.

- Apply on a clean and dry substrate.

- Place a new mixer tip after a 50 seconds break.

Storage

- Remove mixer tip.

- Clean cartridge.

- Put cap back in place.

For a perfect finish (such as lacquering) we recommend applying a flexible plastic putty.