Multi Staple Repair

STRUCTURAL REPAIR AND MOUNTING OF ALL SYNTHETIC MATERIALS

For all synthetic materials, identification unnecessary.

Without auxiliary products – no primers, no cleaning agents, no preparation.

Also ideal for repairing and strengthening supporting and mounting points.

Packaging

| SKU | EAN | Description | ||

|---|---|---|---|---|

|

360500000 - - Multi Staple Repair | 360500000 | Multi Staple Repair | |

|

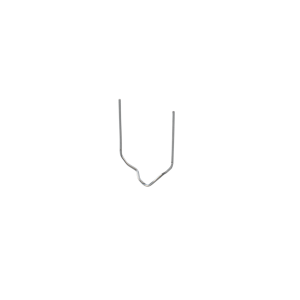

360510000 - 5415207085357 - Multi Staple Repair - Pre-cut staple angle 0.7 mm (100pcs) | 360510000 | 5415207085357 | Multi Staple Repair - Pre-cut staple angle 0.7 mm (100pcs) |

|

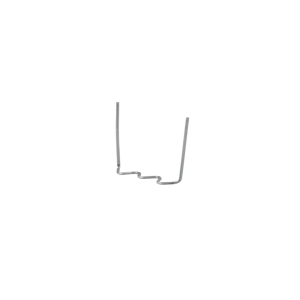

360511000 - 5415207085371 - Multi Staple Repair - Pre-cut staple spiral small 0.7 mm (100pcs) | 360511000 | 5415207085371 | Multi Staple Repair - Pre-cut staple spiral small 0.7 mm (100pcs) |

|

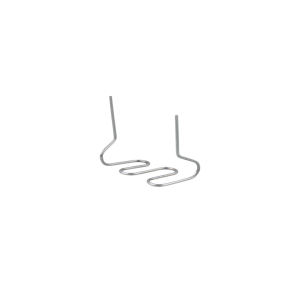

360512000 - 5415207085395 - Multi Staple Repair - Pre-cut staple winding 0.7 mm (100pcs) | 360512000 | 5415207085395 | Multi Staple Repair - Pre-cut staple winding 0.7 mm (100pcs) |

Description

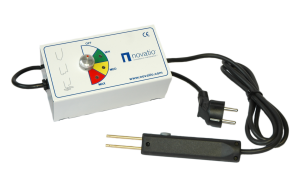

The Multi Staple Repair is a mechanical repair method for plastics. This strong structural repair retains the flexibility needed to re-mount the component. The Multi Staple Repair appliance warms the "staples" in order to embed them in the material to be repaired. The OEM strength of the product is unchanged because no other product has been added. Three types of staples ensure a comfortable and effective repair. The Pre Cut Staple has a breaking point so that the staples break off in the plastic. The gun of the Multi Staple Repair inserts the staples vertically or at an angle of 90° for hard-to-reach places.

Application

- Repair of all synthetic materials, including polyethylene and polypropylene.

- Reinforcement of support and bonding points.

Technical information

Multi Staple Repair

STRUCTURAL REPAIR AND MOUNTING OF ALL SYNTHETIC MATERIALS

- Supply voltage: 230 V - 50/60 Hz.

- Max. power: 35 W.

- Do not use on fibre-reinforced plastics

- Dimensions: 165x87x65 mm.

- Absorption maxima: 160 Ma.

- Two 400 mA fuses.

- Weight: 1.350 kg.

- Safety measures: please consult the safety card.

Instructions

- Connect the apparatus to the mains.

- Move the button to the desired position: LED light on green = minimum position for plastic up to 1.5 mm thick; LED light on yellow = medium for plastic between 1.5 and 2.5 mm thick; LED light on red = maximum position for plastic more than 2.5 mm thick;.

- Select the appropriate staple and place it in the relevant openings in the gun (on the 90° head, depending on the application).

- Place the head of the staple on the desired place of the plastic to be repaired and press the start button of the gun.

- The heat melts the plastic and the staple sinks into the material.

- Turn the gun softly 5° to embed the staple in the plastic and release the start button. Allow the staple to cool before withdrawing the gun.

- Break off the protruding ends.

- Place enough staples to form a sufficiently strong join.

Do not use on fibrous plastics.