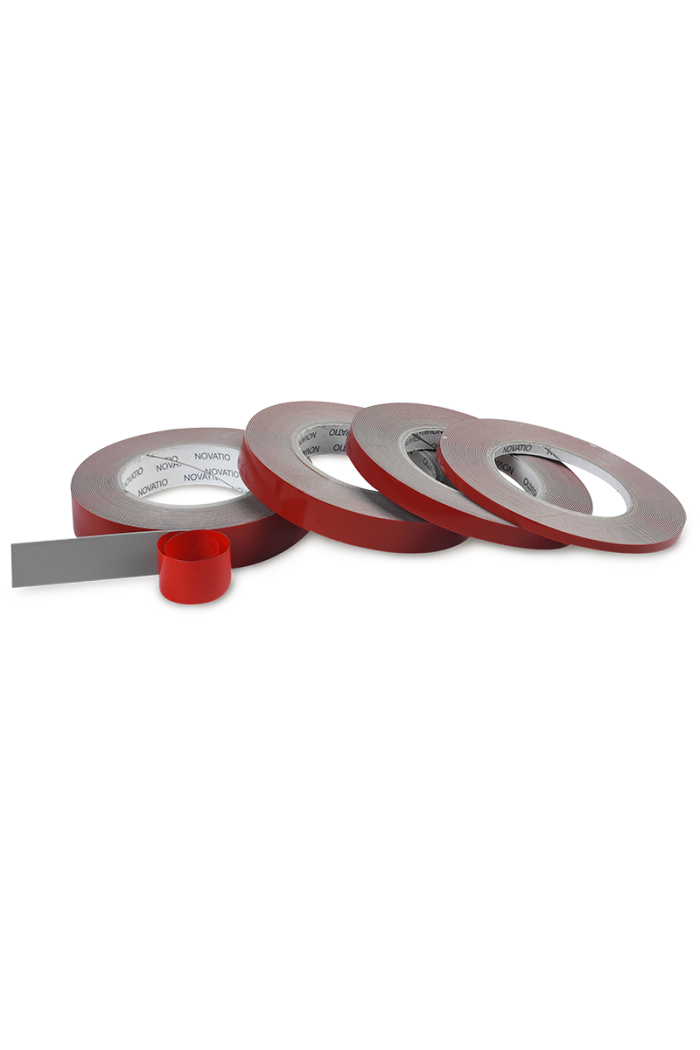

High Tech Tape

DOUBLE-SIDED ACRYLIC TAPE

For permanent mounting on most materials.

Avoid damaging surfaces.

Very high initial strength, but repositionable.

UV, moisture and heat resistant and liquid proof.

Packaging

| SKU | EAN | Description | ||

|---|---|---|---|---|

|

554046000 - - High Tech Tape black - roll 4mm / 10m | 554046000 | High Tech Tape black - roll 4mm / 10m | |

|

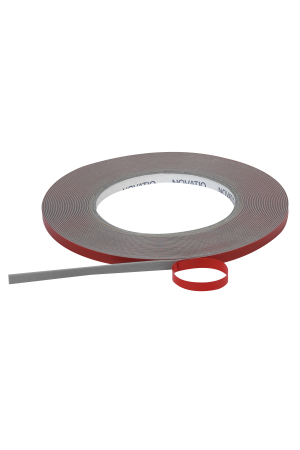

554068000 - - High Tech Tape grey acrylic - roll 6mm / 10m | 554068000 | High Tech Tape grey acrylic - roll 6mm / 10m | |

|

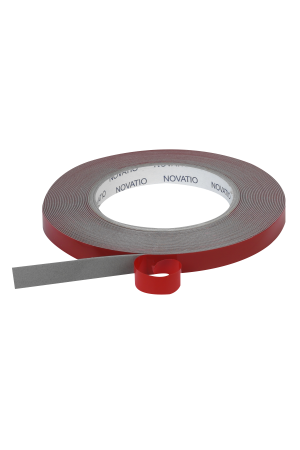

554128000 - - High Tech Tape grey acrylic - roll 12mm / 10m | 554128000 | High Tech Tape grey acrylic - roll 12mm / 10m | |

|

554129390 - - High Tech Tape black - roll 12mm / 33m | 554129390 | High Tech Tape black - roll 12mm / 33m | |

|

554198000 - - High Tech Tape grey acrylic - roll 19mm / 10m | 554198000 | High Tech Tape grey acrylic - roll 19mm / 10m | |

|

554258000 - - High Tech Tape grey acrylic - roll 25mm / 10m | 554258000 | High Tech Tape grey acrylic - roll 25mm / 10m |

Description

The tape has a closed cell structure, is therefore 100% liquid-tight and guarantees structural bonding. High Tech Tape has a high chemical resistance and is temperature resistant from -30 ° C to + 150 ° C. The protective film is easy to remove.

Application

- sanitary and kitchen arrangement: bonding of different accessories and fittings on formica, tiles, metal, inox, lacquer, glass,...

- name- and information plates for permanent attachments

- electronics: rails in switch boxes, assembling of all electronics components, even at high temperature fluctuations

- automotive: bonding of decorative frames, emblems, electrical components, decorative covers on side mirrors

- heavy duty: bonding of roof- and wall panels on framework from buses and trucks, protective strips of vestibules, mirrors, number plates,...

Technical information

High Tech Tape

DOUBLE-SIDED ACRYLIC TAPE

- Adhesive: acrylic through and through.

- Protective foil: red polyethylene.

- Colour: grey acrylic.

- Pressure resistance: cures by pressing.

- Temperature resistance: for 4 hours 150° for 200 hours 90°C.

- Solvent resistance: non-soluble.

- UV-resistance: OK.

- Liquid density: perfect.

- Shearing force: 72 N/cm².

- Max. Tensile strength: 82 N/cm².

- Density: 740 kg/m².

- Thickness: 0.8 mm.

- First test foundations based on PE, PP, silicones and bitumen for adhesion.

- Immediate adhesive strength: after 20 min. 30% adhesive strength, after 24 hours 60% adhesive strength and after 72 hours 100 % adhesive strength.

- Shelf life: 36 months, keep dry, cool and frost-proof.

Instructions

Apply on clean and dry surface.

If necessary, clean with Safety Clean and / or Multifoam.

Processing temperature between + 15 ° C and + 30 ° C.

High direct adhesion

After 20 minutes = 30% adhesive strength.

After 24 hours = 60% adhesive strength.

After 72 hours = 100% adhesive strength.

Heating up glued pieces accelerates the adhesive force.

Ex. after 5 minutes at 65 ° C = 80% adhesive strength.

After 1 hour at 65 ° C = 95% adhesive strength.

Treating difficult plastics with Seal & Bond Special Primer can improve adhesion, as well as increasing the adhesion surface by sanding.