MFL-2480 2K Metal Filler

2-COMPONENT METAL REPAIR

Safe alternative to tin solder

Can be sanded quickly

Non-shrink

Strong adhesion to all metals

Packaging

| SKU | EAN | Description | ||

|---|---|---|---|---|

|

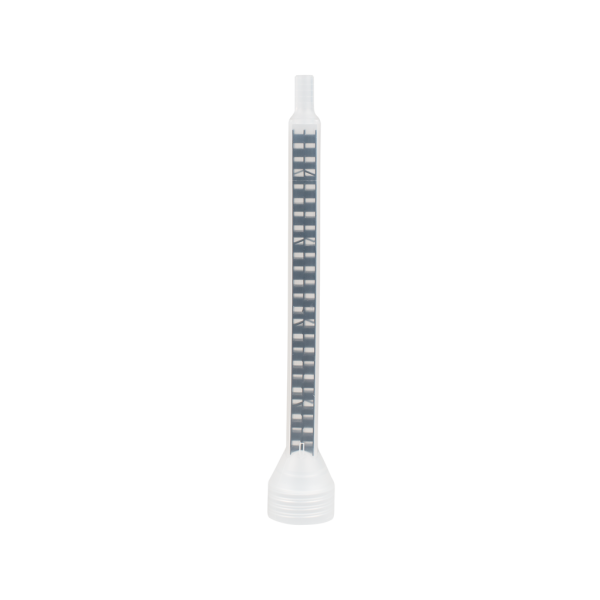

639001000 - 5415207084282 - MFL-2480 2K Metal Filler - cartridge 195ml | 639001000 | 5415207084282 | MFL-2480 2K Metal Filler - cartridge 195ml |

Description

MFL-2480 2K Metal Filler is a lead-free alternative to tin solder when restoring all steel and aluminium surfaces. Low temperature processing prevents deformation of the sheet material.

Fast curing 2-component epoxy with good workability and high filling capacity. Curing can be accelerated by heating with hot air or infrared.

After curing, it is easy to work with and forms an excellent base for further finishing with all types of filler.

MFL-2480 2K Metal Filler provides strong corrosion protection without the risk of delamination.

Application

- Repairing damaged body panels

- Finishing contours

- Repairing hard to reach places

- Repairing welded joints

Technical information

MFL-2480 2K Metal Filler

2-COMPONENT METAL REPAIR

- Type: 2-component epoxy.

- Colour: light grey.

- Density: 1.35 +/-0.05.

- Shape: paste.

- Application temperature (substrate): +10°C /+30°C.

- Curing (23°C): mixing time: 10 minutes.

- Open working time: 25 minutes:

- Sandable 23°C: 2–3 hours

- Sandable 45°C: 20 minutes

- Hardness: shore D 80.

- Tensile strength: 34 N/mm².

- Elongation at break: 10%.

- Adhesion strength (23°C, 1 mm thickness):

- Cold rolled steel (CRS): 16 N/mm².

- Stainless steel: 13 N/mm².

- Galvanised steel: 14 N/mm².

- Aluminium: 10 N/mm².

- Shelf life: store between +15°C and +30°C. 18 months in closed packaging. Can be stored for several weeks in opened packaging, with mixer tip fitted.

Instructions

MFL-2480 2K Metal Filler can be used with manual, electric or pneumatic gun.

Preparation

- Roughen the material thoroughly, remove dust and degrease with Safety Clean.

- Then clean deeply with Multifoam and blow dry.

Usage

- Pattern preparation

- Remove the cap from the cartridge.

- Place the cartridge in the gun and pump until both components come out of the cartridge evenly.

- Place the mixer tip on the cartridge and cut to the desired nozzle size if necessary.

- First spray out 2.5 to 3 cm of product. This is not to be used.

- Apply sufficient product for the repair and spread it out with a spatula. Shape it as best as possible within the time available (25 minutes at 23°C).

- Let it harden for 2–3 hours at room temperature. When heated to 45°C (infrared, warm air) the curing process is accelerated and can be sanded after just 20 minutes.

- Clean materials and spilled product with Safety Clean and/or Nova Wipe.

- After a 10-minute break, use a new mixer tip.

- For storage: leave mixer tip in place. Change mixer tip next time you use it.