Seal & Bond MS50 2-K

2K CONSTRUCTION ADHESIVE AND SEALANT IN HANDY 1K CARTRIDGE

Fast curing to the core, even in extremely thick layers.

High tensile strength, UV and weather resistant.

Perfect adhesion on most materials without the use of primer.

Can be painted quickly with both solvent-based and water-based paints, even wet on wet.

Packaging

| SKU | EAN | Description | ||

|---|---|---|---|---|

|

526106000 - 5415207044019 - Seal & Bond MS50 2-K black - cartridge 280ml | 526106000 | 5415207044019 | Seal & Bond MS50 2-K black - cartridge 280ml |

Description

Seal & Bond MS50 2-K is a 2-component system in a 1- component cartridge for bonding and sealing. Seal & Bond MS50 2-K has a very fast internal polymerisation without shrinkage and meets the highest and most recent norm for garage, industry and bodywork repairs: DIN ISO 868. Seal & Bond MS50 2-K is UV- and weather- resistant, does not get mouldy and is odourless. Seal & Bond MS50 2-K adheres to most current materials: varnished and galvanized surfaces, ferrous and non-ferrous metals, steel, aluminium, lacquer, varnish, polyester, wood and most synthetic materials. Seal & Bond MS50 2-K can be re-used after opening.

Application

Automotive:

- bonding and sealing of spoilers, body kits, construction sills,...

- ideal for the mounting of cargo platforms and side walls of refrigeration cars, delivery vans,...

- installation of sunroofs

- sealing of water leaks in boots

- bodywork parts with a covering function can be glued. This is completely in conformity with the GOCA standards of the car inspection PL002-06 under notion III.

Industry:

- fast gluing of bullet-proof glass

- bonding of mirrors, natural stone, plexiglass, lacquered surfaces, polycarbonate, acrylate, without corrosion or formation of stains (see how to use)

- gluing of stainless-steel kitchens, bathrooms and industry

- developing and repairing of rubber sealings

Technical information

Seal & Bond MS50 2-K

2K CONSTRUCTION ADHESIVE AND SEALANT IN HANDY 1K CARTRIDGE

- Flow: 5 bar / 3 mm / 23°C > 140gr/min.

- Pot life 23°C: 15 to 30 minutes.

- Curing time 20°C:

- primary curing: 1 hour (Shore A: 5);

- processable: 2-3 hours (Shore A: 15-2);

- mechanically resistant: 24 hours (Shore A: >30);

- fully chemically resistant after 7 days.

- Hardness DIN 53505: 50 Shore A.

- Tensile strength: 210 N/cm².

- Tear strength: >73 N/cm² DIN 53507.

- Ultimate elongation 7 days 20°C: >600%.

- Thermal stability: -40°C to +95°C (180°C shortly).

- Specific gravity: ca. 1.4 +/- 0.1 kg/dm³.

- Volume shrinkage after curing: none (<1%).

- Adherence: to most surfaces. Attention: bad adherence to PE, PR, silicones.

- Chemical resistance: is resistant to diluted acids, alkali, aliphatic solvents, oils greases, water and seawater; moderate resistant to esters, ketones and aromatics; not resistant to acids and chlorinated solvents.

- Shelf life: 15 months, keep dry, cool and frost-proof.

- Safety measures: consult the Safety Data Sheet.

Instructions

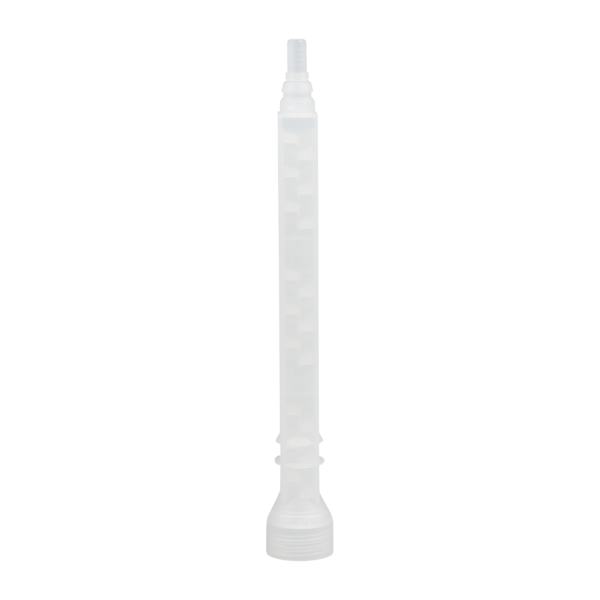

- Pump without mixing tip until the two components flow proportionately.

- Fit the mixing tip and spout 5 cm until you obtain a homogeneous colour.

- Apply on a clean and stable substrate; clean with Safety Clean and/or Multifoam if necessary.

MS50 2-K can be removed with Safety Clean when still fresh.

Remove mixing tip after use.

Store with sealing caps back on.

Processing time is 15 minutes.

After 20 minutes of inactivity, replace mixing tip.

When using a pneumatic gun: only with a telescopic plunger.

Test before application on polycarbonate concerning adhesion and exclusion of tension cracks.