Bonding LSE materials with Novatio NAH-1100

Plastics are playing an increasingly important role in the manufacturing industry. The technical qualities of different types of plastics make it possible to create complex shapes with high material strength and low weight. The development of 3D printing only reinforces the importance of these materials.

However, plastics are often difficult to bond. The bonding ability is mainly determined by the surface energy, a material property that is inherent to the type of plastic. Plastics such as polyethylene (PE) or polypropylene (PP) are very difficult to bond due to their low surface energy. In many cases, you have to resort to thermal welding or mechanical connection for these 'Low Surface Energy' (LSE) plastics.

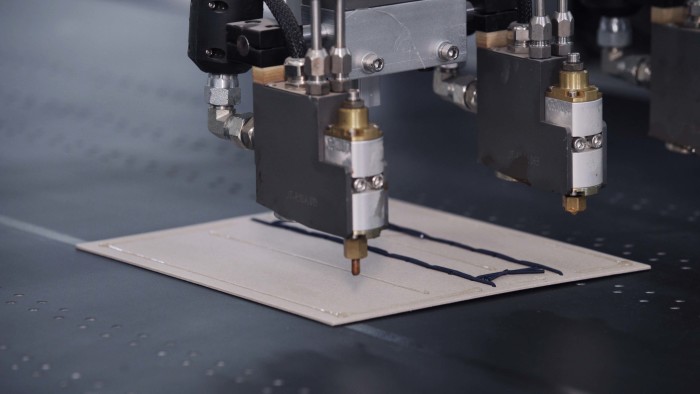

Hybrid MS polymers are an interesting, widely applicable and more environmentally friendly alternative for more classic adhesives such as polyurethane. They are safe to use, cure at room temperature and are available in different degrees of hardness and elasticity. Hybrid MS polymer adhesives are extremely suitable for automated and/or robotic applications. The combination of adhesion and flexibility makes them suitable for both bonding and sealing.